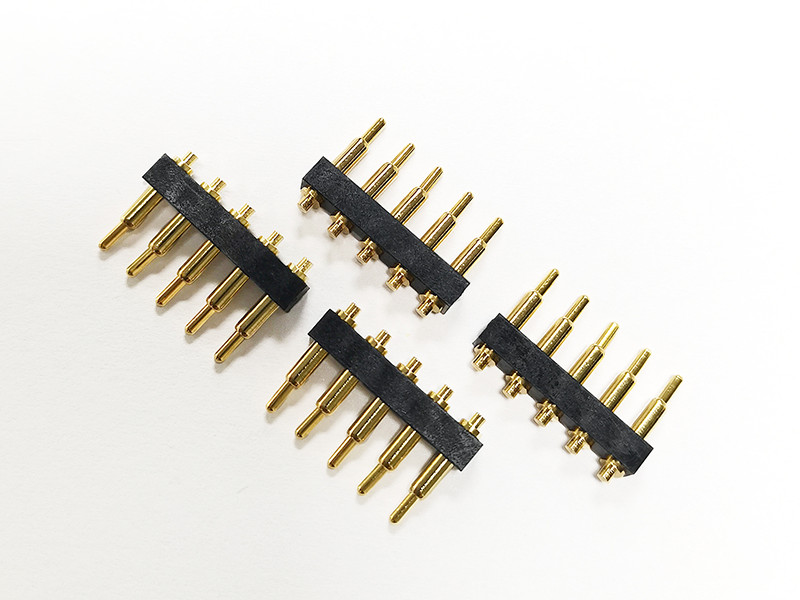

Pogo pin are the most commonly used connectors for most digital electronic products. It is mainly composed of a needle and a needle spring. Pogo pins are divided into different types according to different requirements of customers. So what are the most practical and common types of pogo pins? Today I will introduce to you: pogopin spring thimbles can be divided into flat bottom type, plug-in type, curved type, double needle shaft type, screw type, tin cup type, side hole type and high current type.

The pogopin spring ejector pin has good stability, and the bottom of the needle tube adopts a flat bottom design, which is convenient for welding with the PCB board. Compared with the other three, it has the longest applicability, the simplest process, and the most economical choice with the same height and the same gold plating thickness.

There is a positioning pin at the end of the plug-in pogo pin spring thimble shaft, which will not deviate when soldered to the PCB board, and the positioning effect is good. In order to better weld the single pin on the PCB board and other equipment, the appearance style can be made into a 90-degree bent angle and a right-angle plug-in single pin according to the charm of the customer.

The design of the side hole pogopin spring thimble greatly reduces the thickness of the product, which is suitable for the battery connection part of the current ultra-thin products. The design of the positioning column is more conducive to the precise positioning of the product.

The design of double-needle pogopin spring thimble and probe adds a small head to the standard single-needle pogopin spring thimble to achieve double-sided conductive performance, which facilitates better transmission and provides more flexible space for designers design. A small head is added to the standard single-pin pogopin spring thimble to achieve double-sided conduction for better current transmission.

The tail of the curved pogopin spring thimble is curved, which provides designers with more choices in space utilization.

In addition to the above pogopin spring thimbles, there are also standard pogopin spring thimbles, which are generally customized according to customer products, rarely universal, and the price is relatively expensive.

Pogopin spring thimble pins are made by stamping, electroplating, riveting and other processes. Depending on the scope of use, different types of pogo pins are available. The pogopin spring thimble is not necessarily more expensive the better. We need to choose the appropriate pogopin spring thimble type according to our own equipment.

Post time: Apr-07-2023